Diesel: Technical and Economic Benefits

for Industrial Operations

Currently, companies that rely on diesel engines—such as shrimp farms, transportation providers, and various industrial sectors—face ongoing challenges in maintaining their fleets. Engine wear, high maintenance costs, and the constant need to optimize performance are just a few of the issues impacting both operational efficiency and profitability.

In this context, bypass filtration emerges as an innovative solution that not only extends engine life but also improves performance and significantly reduces operating costs. This whitepaper explores the fundamental principles of bypass filtration, its technical and economic benefits, and how it can transform the operation of your diesel engine fleet.

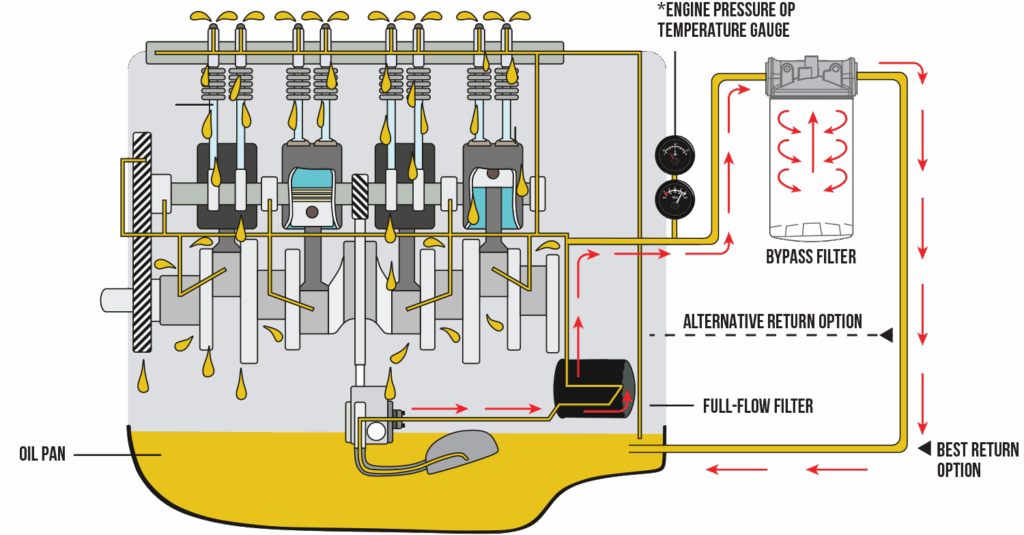

According to Noria Corporation, high levels of contamination in engine lubricating oils prevent the use of filters with very fine pores in full-flow systems, as these would lead to premature clogging. To address this issue, bypass filters are recommended. These filters divert only 5% to 10% of the engine’s lubrication flow through an ultra-high-efficiency filter before returning the cleaned oil directly to the sump.

With bypass filtration, the flow rate is significantly reduced, allowing for much smaller pore sizes while maintaining a normal pressure differential. The result is significantly cleaner oil returning to the oil reservoir.

This approach enables the removal of finer soot suspensions and polar insolubles that are not effectively controlled by the full-flow filter. When used in combination with a full-flow filter, bypass filtration delivers key advantages, including lower wear particle generation rates, reduced oil consumption, improved combustion efficiency, and extended oil service life.

In a case study conducted by General Motors and published by the Society of Automotive Engineers (SAE), it was found that engine life could be extended by a factor of eight when using 5-micron bypass filters, compared to standard 40-micron filtration systems.

1

Basic Principles of

Bypass Filtration

Bypass filtration is an advanced technology that enhances engine oil quality without compromising the main lubricant flow. Unlike traditional systems, which primarily filter out larger particles, bypass filtration systems remove microscopic contaminants that are responsible for long-term engine component wear.

- Basic Operation: In a bypass system, a small portion of the engine oil is diverted to a secondary filter, where finer particles and other contaminants—typically missed by conventional full-flow filters—are effectively removed. This process keeps the oil cleaner for a longer period, reducing wear and improving engine efficiency.

- Key Benefit: The engine operates with higher-quality oil for extended periods, which reduces internal friction and prevents damage to critical components such as pistons, valves, and bearings.

2

Technical Benefits of

Bypass Filtration

a) Extended Engine Life: The primary technical benefit of bypass filtration is the extension of engine service life. By removing microscopic particles that cause wear, the engine maintains optimal performance for significantly longer periods, delaying costly repairs and component replacements.

b) Reduced Maintenance Costs: Bypass systems prevent the buildup of sludge and deposits inside the engine, reducing the need for frequent maintenance. With fewer harmful particles in the oil, blockages and mechanical failures are minimized, lowering downtime and repair costs.

c) Improved Operational Efficiency: A clean engine is an efficient engine. Bypass filtration enhances operational efficiency by ensuring the engine runs at more stable temperatures and with reduced internal friction. This not only boosts overall performance but also contributes to improved fuel economy.

d) Reduced Emissions: By improving engine efficiency, bypass filtration also helps reduce emissions. An engine free from contaminants produces fewer exhaust gases, aiding companies in complying with stricter environmental regulations and improving sustainability efforts.

In the document Impact of particulate matter and fuel quality on the life of diesel engines and the environment – Part 2, written by Engineer Gerardo Trujillo, the following is stated:

“Maximum solid contamination levels should be ISO 18/16/13 (lower is better), in accordance with the international ISO 4406 standard. To achieve these cleanliness levels, fleet maintenance strategies must include careful management of air filters, proper oil application procedures, and fuel cleanliness. The solid particles that destroy engines typically enter through the air intake system (pre-filters, primary and secondary filters), which must be handled with care. Common practices such as blowing out filters with compressed air or washing them to reuse after saturation should be avoided.

New lubricants must be filtered before being introduced into the engine, and engine oil filters must be efficient enough to achieve and sustain ISO 18/16/13 levels. Supplemental filtration options, such as bypass filters connected to the engine’s oil pressure line—either high-efficiency synthetic media filters or centrifugal systems—are capable of removing particles down to 1 micron, including agglomerated soot. This allows for even higher cleanliness levels and extends both oil and engine filter life. Furthermore, fuel and intake air cleanliness are critical to preventing combustion byproducts from contaminating the oil and causing abrasive wear.”

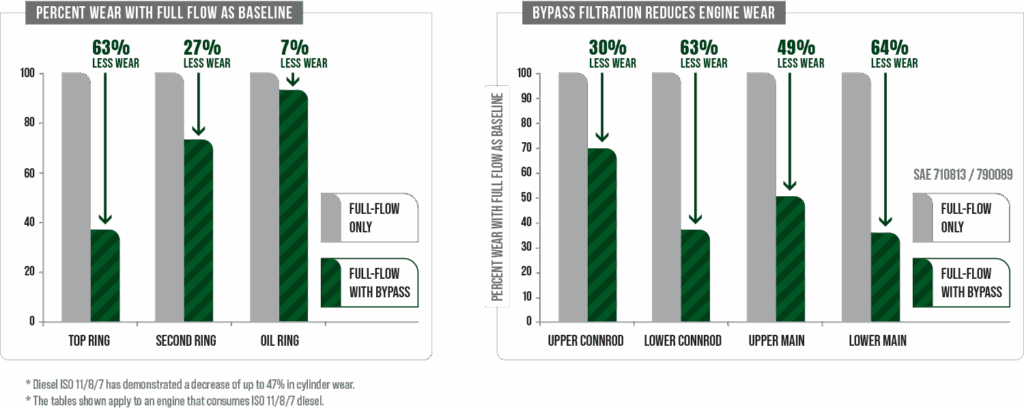

It has also been demonstrated that when using fuel that meets ISO cleanliness code (11/8/7) and implementing a bypass filter, the following results can be achieved:

The FMS bypass oil filtration system ensures that the oil in the sump is continuously cleaned while the engine is running, achieving the optimal cleanliness target recommended by engine manufacturers (ISO 16/14/12 or better). As a result, engine oil performance will exceed expectations.

3

Economic Benefits of

Bypass Filtration

a) Reduced Oil Consumption: Bypass filtration extends the service life of engine oil, reducing the frequency of oil changes. This not only lowers oil procurement costs but also minimizes waste and the need for disposal of contaminated oil, contributing to more cost-effective and environmentally friendly operations.

b) Lower Operating Costs: Thanks to its ability to reduce engine wear and mechanical failures, bypass filtration systems significantly lower overall operating costs. Engines require less maintenance and fewer replacement parts, resulting in reduced downtime and increased productive operating hours.

c) Sustainable Return on Investment (ROI): The initial investment in a bypass filtration system is quickly recovered through savings in fuel, oil, repairs, and components. Businesses can expect a strong long-term ROI driven by lower operating costs and improved engine reliability.

d) Extended Fleet Service Life: By implementing bypass filtration, diesel engine fleets can operate longer without the need for costly replacements or major overhauls. This extends asset longevity and enhances long-term profitability.

4

Applications

Vehicular, stationary, and generation.

5

Implementation and

Recommendations

a) Simple and Efficient Installation: Bypass filtration systems are easy to install and do not require complex modifications to existing diesel engines. The installation is performed quickly and efficiently, minimizing equipment downtime.

b) Minimal Maintenance: Once installed, the system requires minimal maintenance. Bypass filters are low-cost and easily accessible, making replacement straightforward without interrupting daily operations.

c) Implementation Process:

Initial Assessment: Analyze your needs and determine the appropriate system.

Quick Installation: Implementation without operational interruptions.

Monitoring and Optimization: Ensure regular inspections are conducted to maximize performance.

Conclusion

Bypass filtration is much more than just an improvement in engine maintenance technology. It is a strategic solution that provides significant technical and economic benefits for any business relying on diesel engines. From extending engine life to reducing operational costs, bypass filtration ensures more efficient, cost-effective, and environmentally friendly operations.