PARTICULATE CONTAMINATION

REMOVAL

Contamination control at dispatch is a fundamental part of best practice. Our bottom-connected lockbox filters are the only ones that can be installed on the ridge of subway tanks and handle multiple dispensing guns.

WATER / EMULSIONS COALESCENCE REMOVAL

Water and emulsions cause up to 15% of power loss, thus up to 15% increase in fuel consumption. All ISO 4406 contamination control plans must include water and emulsions with SAE J1488 certified systems.

GETTING MAXIMUM

CLEANLINESS IN

-

BETA

- FLOW

- DHC

ISO 16889

BETA

This is the correct expression that defines the efficiency of a filter.

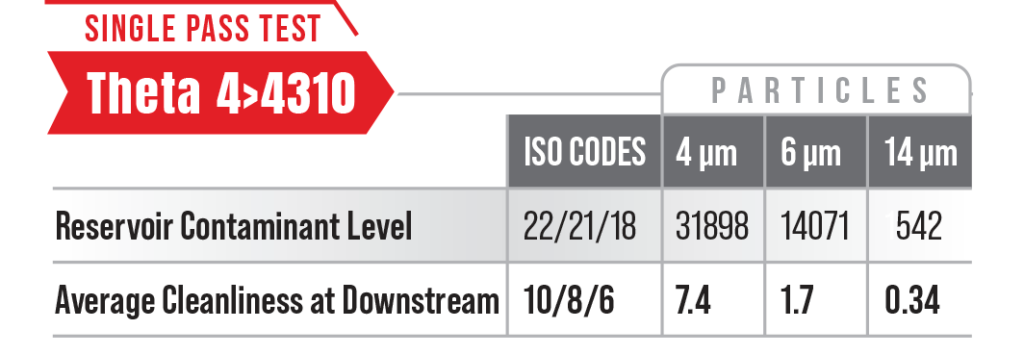

ENTRY VS EXIT ISO

ENTRY VS EXIT PARTICLES

REAL CONDITION VS OPTIMAL GOAL

ISO 16889

FLOW

The test must be performed at a higher flow than the filter will be exposed to in real conditions to guarantee optimum performance.

ISO 16889

DHC

The DHC is the dirt holding capacity or the storage capacity of grams.

The filter with the highest DHC will be the one that will filter the most gallons and depending on the cost will be the most economical option.

-

WATER / EMULSIONS

- FLOW

SAE J1488

The efficiency of a coalescing filter lies in its ability to extract water and emulsions; this is why the SAE J1488 test must be required.

SAE J1488

The flow to which we will expose the coalescing filter must be the same to which the filter was certified.

Every time we install a filter above its flow capacity, a radical drop in efficiency is to be expected.

Many manufacturers recommend their filters at flows higher than the tests carried out; For this reason, it is important to request the complete information of the test to verify the optimal operating conditions.

SOLUTIONS FOR

EVERY INDUSTRY