Particles and Moisture in Oily Fluid Storage Tanks

(Diesel, Engine Oil, and Hydraulic Oil)

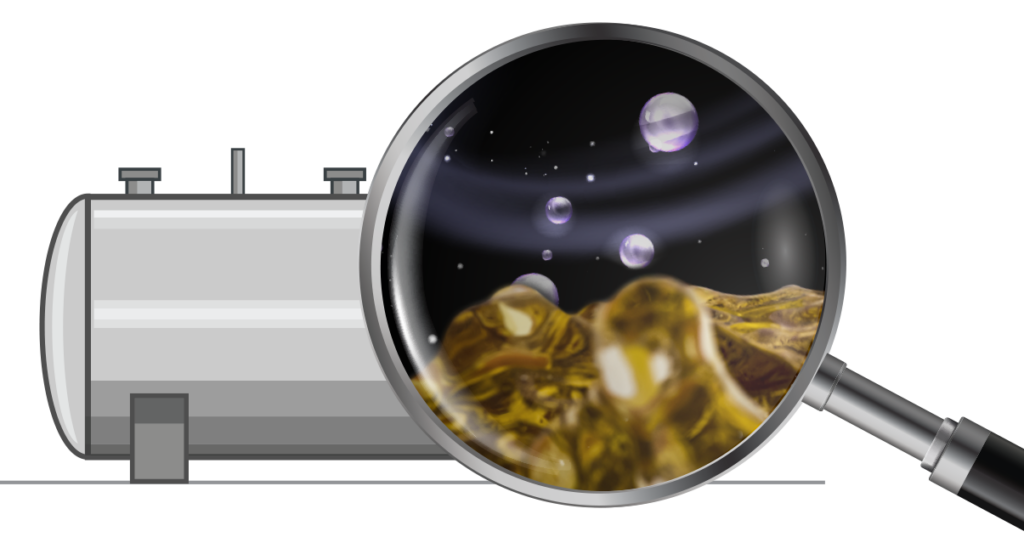

Storage tanks for oily fluids (fuel, lubricating oil, and hydraulic oil) are essential to ensure the continuous and efficient operation of a wide range of industrial equipment, heavy machinery, vehicles, and power systems. However, these tanks are vulnerable to the presence of invisible contaminants such as particles and moisture, which can compromise the quality of the stored fluid, reduce equipment lifespan, and increase operating costs. Lack of control over these contaminants often leads to premature failures, hydraulic system breakdowns, and environmental issues.

This white paper explores how breathers are a key tool for protecting storage tanks and stored fluids against invisible enemies present in the air, offering an effective strategy to preserve the integrity of fuel and hydraulic oil while enhancing the reliability and operational efficiency of facilities.

1. PARTICLES AND MOISTURE

2. The Role of Breathers

3. Applications of Breathers

4. Selecting the Right Breather

1

PARTICLES AND

MOISTURE

Invisible Enemies in the Air

PARTICLES

In any industrial or storage environment, the air is filled with microscopic particles that can enter tanks during filling and emptying cycles. These particles may include:

Dust and dirt: Originating from the environment or during fuel transportation.

Metallic particles: Resulting from normal equipment wear or corrosion.

Biological contaminants: Such as fungal spores or bacteria, which can thrive in humid environments.

These particles can mix with fuel or oil, clog filters, damage system components, and reduce efficiency. In hydraulic systems, particles can damage seals and precision components.

MOISTURE

Water in storage tanks is another invisible contaminant that can enter the system in various ways:

Condensation: Warm, humid air entering the tank cools down and forms water droplets.

Water infiltration: During rain or high humidity, water may enter through tank openings.

Contamination from external sources: Such as seal failures in valves or connections.

Water in fuel or hydraulic oil can have disastrous consequences:

Corrosion of metal components in the tank and connected systems.

Formation of emulsifiers that affect lubrication, reducing the effectiveness of hydraulic oil and fuel.

Reduced effectiveness of additives in the fuel, impacting its performance and quality.

2

The Role of

Breathers

Protection Against Invisible Enemies

Breathers are filtration and dehumidification devices placed on tank openings to prevent airborne contaminants from entering. These vents serve a dual purpose: filtering particles from incoming air and absorbing moisture, thereby protecting the tank’s contents and any connected systems.

How Breathers Work

Particle Filtration: Breathers are equipped with high-efficiency air filters that trap fine particles such as dust and dirt before they can enter the tank. FMS breathers feature a 2-micron particle filter on the top, ensuring that the air entering the tank is completely clean.

Moisture Control: FMS breathers include dehydrators or specially sized absorbents such as silica gel, which retain 80–85% of the air’s moisture. Additionally, they contain molecular sieve material that absorbs the remaining 20–15% of moisture in the air before it enters the tank. This prevents internal condensation and helps maintain the integrity of the stored fluid.

Benefits of Breathers

Corrosion Prevention: By keeping moisture out of the tank, breathers help prevent corrosion of the tank walls and the metallic components of connected systems.

Improved Fluid Quality: By filtering out particles and reducing moisture, breathers preserve the purity of diesel or hydraulic oil, ensuring optimal performance.

Extended Equipment Life: Clean, dry fluid reduces wear on pumps, motors, and valves, increasing equipment reliability and service life.

Reduced Operating Costs: High-efficiency breathers help cut maintenance costs by preventing premature failures and reducing the need for frequent fluid and component replacement.

INLET

X = Replacement Cartridge

Y = Housing with Connector

(with splash protection)

OUTLET

Outlet

(90° Rotated View)

3

Applications

of Breathers

Fuel Storage

Tanks

Breathers in fuel storage tanks prevent oxidation and the formation of gums and deposits that can damage engines and equipment. This is essential in industrial facilities, gas stations, tanker trucks, and power systems operating with high-quality fuels.

Hydraulic Oil

Tanks

Breathers for hydraulic oil tanks protect the oil from contaminants, ensuring efficient lubrication and protecting hydraulic pumps and other high-precision components. This is crucial for heavy machinery, agricultural equipment, industrial control systems, and any application relying on high-pressure hydraulic systems.

4

Selecting the

Right Breather

Not all breathers are the same. It is crucial to select the right breather according to the type of tank and operating conditions. Some key factors to consider are:

- Filtration capacity: Ensure the breather has the capacity to filter the particles present in your specific environment.

- Moisture control: Choose a breather with a high-capacity desiccant if your environment has high humidity or temperature fluctuations.

- Durability and resistance: Breathable must withstand extreme conditions such as high temperatures and corrosive environments.

- Size and ease of installation: The breather must be compatible with your tank’s design and easy to install.

Conclusion

Invisible enemies such as particles and moisture pose constant threats to fuel and hydraulic oil storage tanks. Particle filtration and moisture control through proper breathers are essential measures to protect the quality of oily fluids (fuel, lubricating oil, and hydraulic oil), extend equipment lifespan, and reduce operating costs.