1.Introduction

ISO 4406 is an international standard used to classify the level of solid particle contamination in fluids such as lubricating oils, hydraulic oils, and fuels, based on the particle count greater than 4 µm, 6 µm, and 14 µm per milliliter of sample (ISO, 1999).

Although laboratory sample analysis has traditionally been a common practice in predictive maintenance and lubricant condition monitoring, this method presents critical limitations when it comes to accurately measuring the true cleanliness of a fluid under real operating conditions of a machine or system—particularly in applications that demand high levels of cleanliness (Noria Corporation, 2024).

2. Fundamental Issues of

Laboratory Sampling

- Containers or bottles that are not perfectly clean, introducing their own particles into the sample. Even containers classified as “ultra-clean” may contribute enough residual particles to alter the reported ISO code (CleanControlling GmbH, 2026).

- Improper handling or environmental exposure, such as dust, dirt, or residues originating from hands, tools, or equipment used during the extraction process.

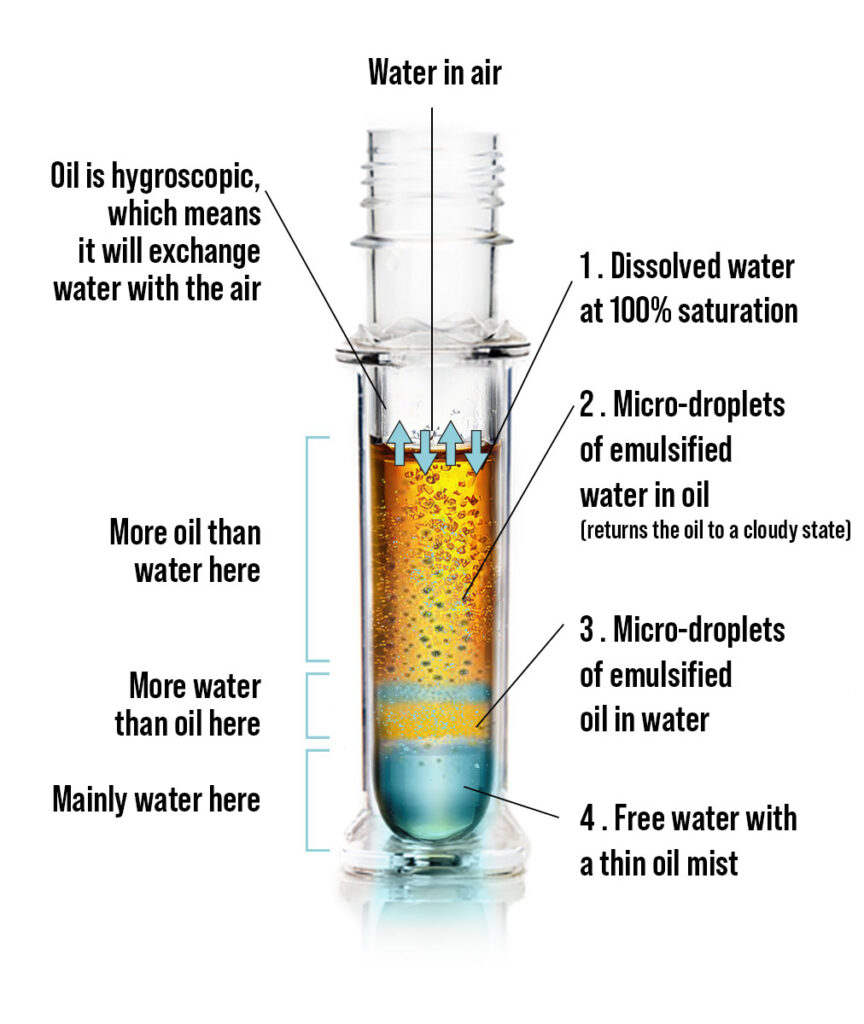

- Inappropriate sampling methods, such as drawing samples from sedimentation zones or from the bottom of tanks—where particles and water tend to accumulate—instead of from representative flow points of the fluid under operating conditions (MP Filtri, 2025).

22.2. Static Nature of the Sample

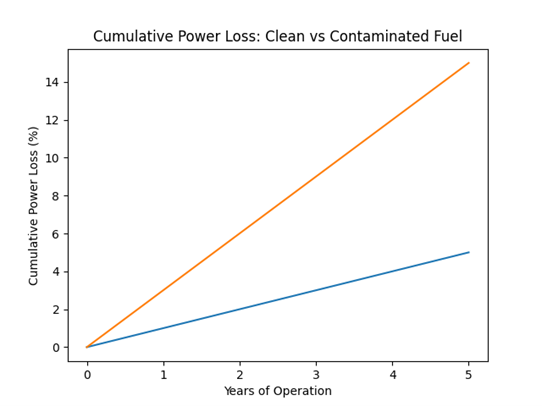

Once collected, a sample represents only a static, momentary condition of the fluid. It does not capture dynamic variations that occur during actual equipment operation, such as:

- Fluctuations in particle concentration resulting from changes in load, pressure, or temperature.

- Generation of wear particles during start-ups, shutdowns, or transient operating conditions, which can only be observed while the equipment is in service (OilSense, 2026).

This static approach limits the predictive value of the analysis and reduces its effectiveness within modern proactive maintenance and operational reliability strategies (Johnson, 2020).

2.3. Dependencia de procedimientos estrictos

The accuracy of ISO 4406 laboratory analysis depends on standardized processes and the proper calibration of measurement instruments, such as automatic particle counters calibrated in accordance with ISO 11171 (ISO, 2017).

However, even under standardized procedures, inherent variations exist in:

- Sample preparation, including degassing, homogenization, and bubble removal.

- Pre-treatment processes and fluid handling.

- Result interpretation by laboratory personnel (Entegris, 2025).

These variabilities introduce uncertainty and may reduce the true representativeness of the fluid’s actual cleanliness level.

3. How to Ensure a Sample

Is Not Contaminated

If traditional sampling is used for ISO 4406 analysis, it is essential to implement strict controls, including:

- Use of absolutely clean equipment and containers, preferably certified in accordance with ISO 3722.

- Installation of dedicated sampling points, located in areas of representative system flow.

- Pre-sampling flushing to remove residual contaminants from valves and lines.

- Trained technicians and documented procedures.

- Transportation and handling practices that keep samples sealed and protected until analysis.

These measures reduce the risk of cross-contamination but significantly increase the time, cost, and complexity of the process (Noria Corporation, 2024).

4. Variability Between Laboratories and Methods

4.1. What They Are and How They Work

In-line laser particle counters are sensors that are directly integrated into the fluid circuit to continuously measure the quantity and size of particles present, automatically reporting the ISO 4406 code without the need to extract samples (OilSense, 2026).

These devices use optical and laser-based technology to detect particles in the flowing fluid and classify them by size in real time.

4.2. Key Advantages

Advantages:

- True system representativeness.

- Continuous, real-time data.

- Reduced risk of cross-contamination.

- Proactive maintenance capability.

- Faster response time

Explanation:

- Measures the fluid under real operating conditions

- Enables immediate detection of contamination increases

- Eliminates human handling of the fluid

- Facilitates early detection of wear and potential failures

- Eliminates delays associated with sample shipping and laboratory analysis

These advantages have led multiple OEMs and reliability specialists to recommend in-line measurement as the preferred practice for critical systems (MP Filtri, 2025).

4.3. Limitations and Considerations

Limitations:

- Initial investment cost

- Calibration and maintenance requirements.

- Does not replace comprehensive laboratory analysis.

Details:

- Higher initial investment compared to traditional sampling

- Requires proper sensor management.

- Physical-chemical and metallographic analyses are still required

Therefore, the recommended approach is the combination of in-line measurement for cleanliness control and laboratory analysis for advanced diagnostics (Entegris, 2025).

5. Recommendations According

to Experts and OEMs

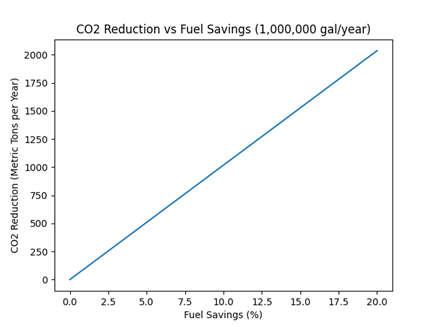

Various manufacturers, reliability specialists, and technical organizations agree that:

- Particle contamination measurement should migrate toward automated and truly representative methods, such as in-line sensors.

- ISO 4406 is a coding standard, not a sampling standard.

- The industrial trend is the integration of continuous monitoring with predictive analytics and asset digitalization (OilSense, 2026; Noria Corporation, 2024).

6. Why In-Line Measurement Is Technically

Far Superior to Laboratory Sampling

The primary reason why in-line ISO 4406 cleanliness measurement is vastly superior to laboratory sample extraction lies in a fundamental physical fact:

the extreme sensitivity of the ISO code to microscopic quantities of solid contamination.

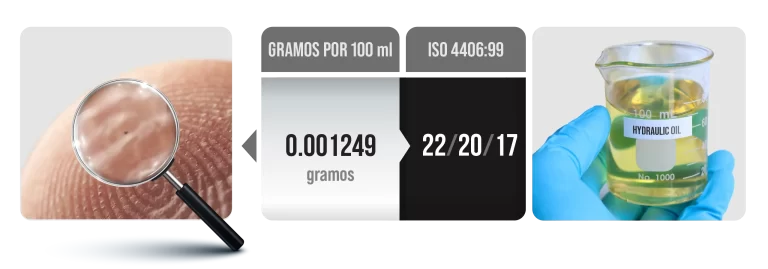

When working with typical laboratory sample volumes (100 ml), only an infinitesimal mass of particles is required for the ISO code to escalate to severely contaminated levels. This condition makes traditional sampling inherently vulnerable to cross-contamination errors, even when strict procedures are followed.

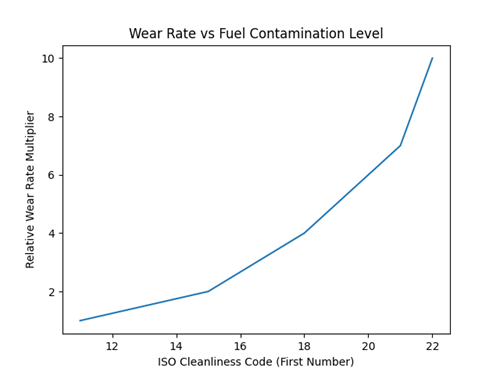

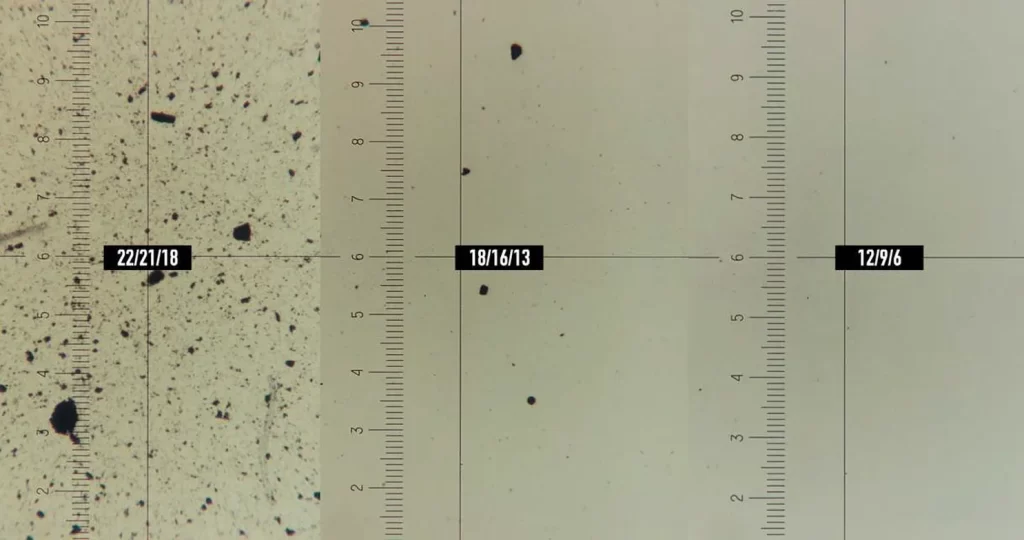

6.1. Extreme Sensitivity of the ISO 4406 Code

To put the magnitude of the issue into perspective, only 0.00125 grams of solid particles (1.25 milligrams) are sufficient to contaminate 100 ml of oil or diesel to an approximate level of ISO 22/21/18.

This mass is so small that it may originate from:

- Micro-residues in a “clean” container

- Invisible ambient dust

- Residues in sampling valves or hoses

- Minimal human handling

In industrial practice, achieving absolute control over these variables is nearly impossible, which makes traditional sampling an inherently fragile method when low cleanliness levels are required.

6.2. Relationship Between Contamination Mass and ISO Code Escalation

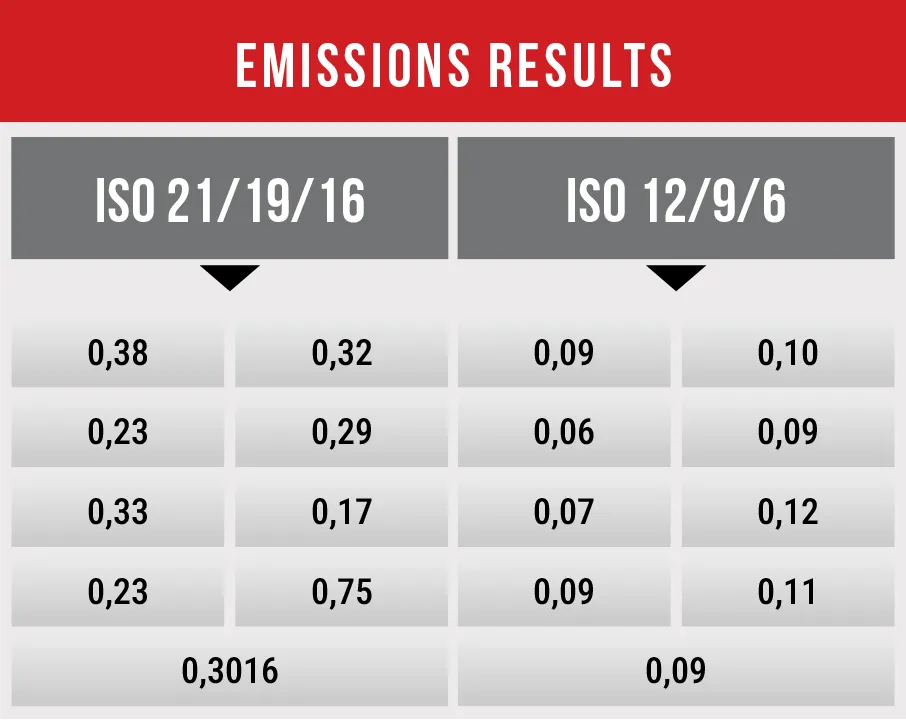

The following table illustrates how decreasing amounts of solid contamination, measured in grams for a 100 ml volume, generate complete step changes in the ISO 4406 code:

· Contamination Mass (g in 100 ml):

· 0,00125 g

· 0,000675 g

· 0,0003375 g

· 0,000168 g

· 0,000084 g

· 0,000042 g

· Approximate ISO Code:

· ISO 22 / 21 / 18

· ISO 21 / 20 / 17

· ISO 20 / 19 / 16

· ISO 19 / 18 / 15

· ISO 18 / 17 / 14

· ISO 17 / 16 / 13

Technical Note: Any minimal external contamination event during sampling is sufficient to invalidate the result.

6.3. Technical Implications for Traditional Sampling

This behavior of the ISO code has critical consequences:

- Sampling does not fail due to poor intent; it fails due to unavoidable physical limitations.

- The higher the required cleanliness level, the lower the reliability of sampling.

- Errors are neither visible nor detectable to the naked eye.

- A high ISO result may reflect contamination introduced during the sampling process, not contamination within the system itself.

For this reason, laboratory sampling cannot guarantee that the reported ISO value faithfully represents the true condition of the fluid in operation, particularly in critical systems.

6.4. Structural Advantage of In-Line Measurement

In-line measurement using laser particle counters eliminates this issue at its root because:

- There is no sample extraction; therefore:

- No bottles

- No handling

- No transportation

- No environmental exposure

- The fluid is measured exactly as it circulates within the system

- The evaluated fluid volume is continuous and truly representative

- Trends are observed, not isolated events

From a metrological standpoint, in-line measurement is not merely an improvement over sampling—it represents a paradigm shift.

6.5. Implications for Industrial Predictive Maintenance

Within predictive maintenance programs—where decisions rely on trustworthy data—in-line measurement:

- Reduces false positives caused by sample contamination

- Enables detection of actual wear particle generation

- Provides early warnings based on trend analysis

- Improves the reliability of predictive models

For these reasons, OEMs, hydraulic system manufacturers, and reliability specialists regard in-line measurement as the only technically sound approach for controlling ISO cleanliness in modern industrial applications.

7. Conclusion

Although traditional sampling and laboratory analysis under ISO 4406 have been valuable tools, they are not sufficient on their own to reliably assess fluid cleanliness in real operating systems.

Cross-contamination, the static nature of sampling, and procedural dependency limit their accuracy. The adoption of calibrated and certified in-line laser particle counters provides more representative, continuous, and actionable data—essential for advanced predictive maintenance programs.

REFERENCES

[1] CleanControlling GmbH. (2026). Particle contamination in oils and lubricants: Particle contamination analysis according to ISO 4406. CleanControlling Technical Publications.

[2] Entegris, Inc. (2025). ISO 4406 testing: Contamination particles in oil. Entegris Application Note.

[3] International Organization for Standardization. (1999). ISO 4406: Hydraulic fluid power—Fluids—Method for coding the level of contamination by solid particles. ISO.

[4] International Organization for Standardization. (2017). ISO 11171: Hydraulic fluid power—Calibration of automatic particle counters for liquids. ISO.

[5] Johnson, D. (2020). Predictive maintenance through fluid contamination monitoring. Journal of Maintenance Engineering, 8(3), 112–125.

[6] MP Filtri. (2025). Cleanliness monitoring of hydraulic systems: APCs and continuous monitoring.

MP Filtri Technical Paper.

[7] Noria Corporation. (2024). What is the importance of the ISO 4406 cleanliness code? Noria Publishing.

[7] OilSense. (2026). Condition monitoring oil sensors: Real-time oil quality monitoring. OilSense Technical Documentation.