THE RIGHT ORDER

FUEL

Contaminated fuel causes high levels of engine wear:

- Injection System

- Cylinders – Compression

- Contaminated Oil

- Component Wear

- Reduced Intervals

AIR FILTER

Careful attention to the correct choice of air filter is essential for optimum engine performance.

- Cleaning method

- Change Interval

- Filter quality

Lubricant

It is always important to choose the right lubricant of the highest quality so that the best results are obtained by combining correct and predictive maintenance practices:

- Type and brand of oil

- Continuous analysis

Filtration

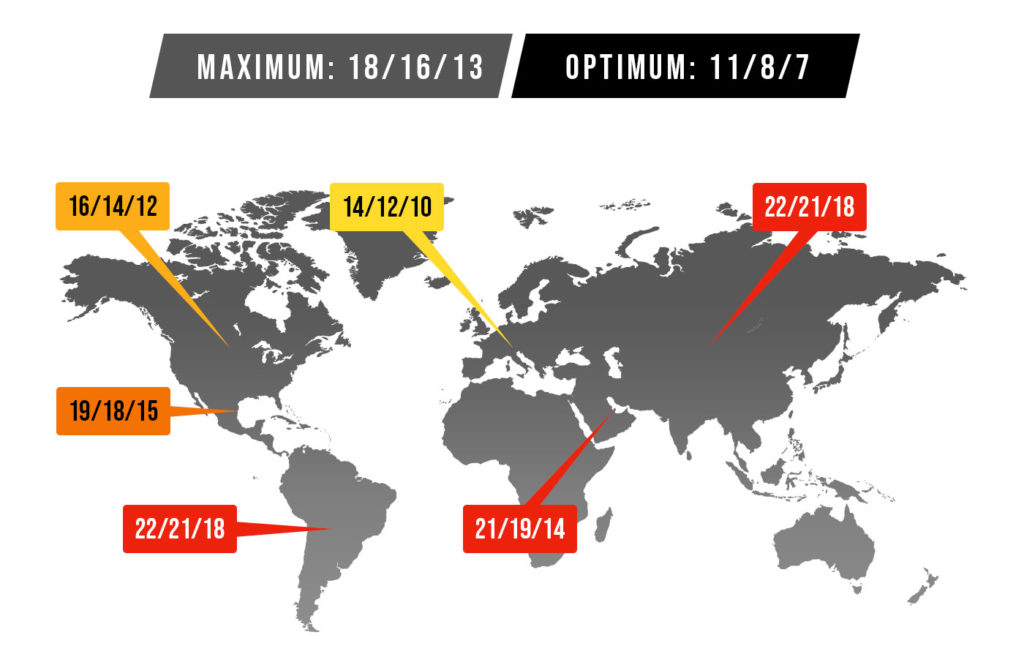

An engine should remain clean with a maximum ISO 4406 17/16/13, for the effect the combination of the above practices is indispensable together with the improvement of the filtration.

- Full-Flow Filters

- Bypass filtration

THE FMS

PROPOSAL

Consultancy

An expert advice that allows users to know their current condition and the engineering applied to their needs in order to maintain an operation within the ISO 4406 standard according to the engine manufacturer’s stipulations.

Validation

Using certified equipment, the supplier is audited and the results of the contamination control practices are confirmed in real time and online for the user to validate the success of the FMS proposal.

ISO Supply

FMS awards “at no cost the equipment necessary for optimal contamination control; against the purchase of filter elements without any contract. The costumer measures the results and decides to proceed without obligation.

CONDITION

ASSESSMENT

Understanding the impact of Diesel!

An engine that consumes 10 gal/hr will burn 10,000 gallons of fuel in 1,000 hours of work and will have performed an average of 4 oil changes every 250 hours.

An ISO 22/21/18 diesel contains 473 grams in 10,000 gallons of volume, therefore 118.25 grams were combusted every 250 hours or oil change interval, with 1.5 grams being enough to contaminate 10 gallons of oil to increase fuel consumption over the 3% and cause premature wear and loss of compression.

START-UP

STEPS TO AN ULTRA CLEAN & DRY DIESEL

ULTRA CLEAN DIESEL

LUBRICATION

Pre-Project

PILOT PLAN

ENGINE OIL BYPASS

The FMS bypass ultra-filtration system is a secondary filtration unit that aims at super-cleaning the engine oil through very high efficiency: it has a high contaminant holding capacity, and retains even the smallest particles.