Loss of compression in engines: what causes it?

Premature compression loss in internal combustion engines is a critical issue that significantly affects engine performance, efficiency, and service life. This phenomenon can be attributed to a variety of factors, among which the type of fuel used plays a key role. Below, we will examine the relationship between fuel and premature compression loss, highlighting the importance of selecting the appropriate fuel to ensure engine health and optimal performance.

What Is Premature Compression Loss?

Premature compression loss refers to the abnormal decrease in compression pressure within an engine’s combustion chambers. This condition can be caused by several factors, including wear of piston rings, valves, or cylinder walls, as well as the buildup of carbon deposits or the degradation of seals and gaskets. When compression loss occurs, engine efficiency is reduced—leading to decreased power output, increased fuel consumption, and a higher risk of mechanical failures.

The role of fuel in premature

compression loss

The type of fuel used in an internal combustion engine can have a significant impact on the onset and severity of premature compression loss. Low-quality fuels, particularly those with high levels of impurities or undesirable additives, can contribute to the accelerated wear of engine components. Conversely, high-quality fuels—with proper formulation and controlled composition—can help minimize deposit formation, reduce friction, and extend engine lifespan.

The Importance of Choosing the Right Fuel

Selecting the appropriate fuel is essential for preventing premature compression loss and ensuring long-term engine performance. By choosing a high-quality fuel, diesel engine operators can benefit in several key ways:

Reduced wear of engine components: Premium fuels help reduce deposit buildup and minimize friction between moving parts, thereby extending component life.

Improved efficiency and performance: Clean, high-grade fuels support more complete and uniform combustion, resulting in greater power output and improved fuel economy.

Lower pollutant emissions: Because they burn more efficiently, quality fuels produce fewer harmful emissions, contributing to reduced air pollution and a cleaner environment.

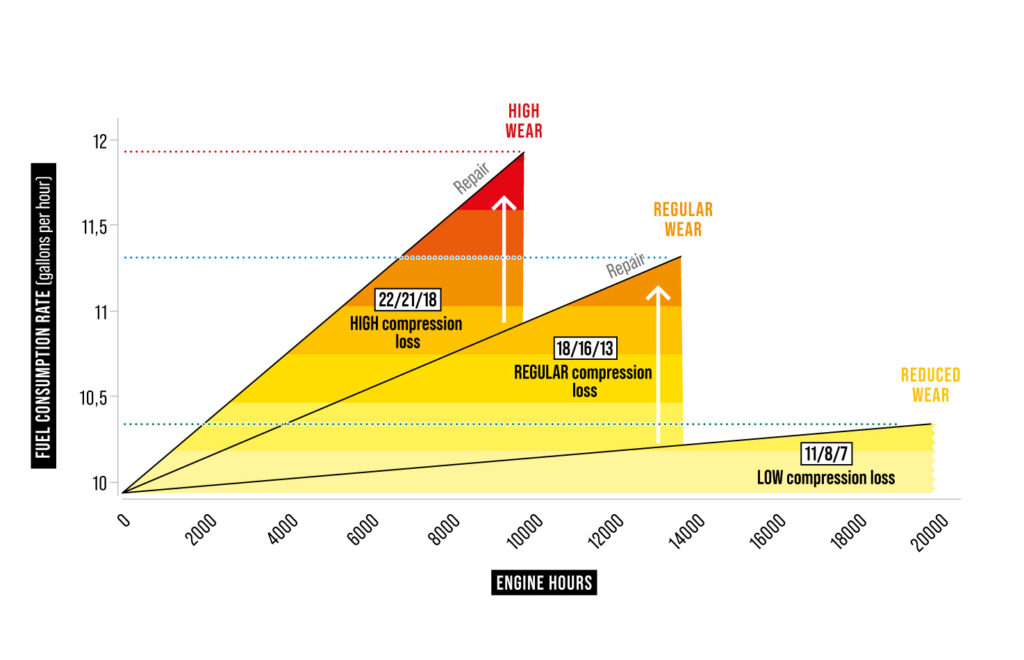

The use of on-spec fuel not only contributes to extending the service life of the engine and its components such as injectors, DPF, service filters, and even the lubricant but also significantly improves fuel consumption efficiency, potentially reducing fuel usage by up to 17%.

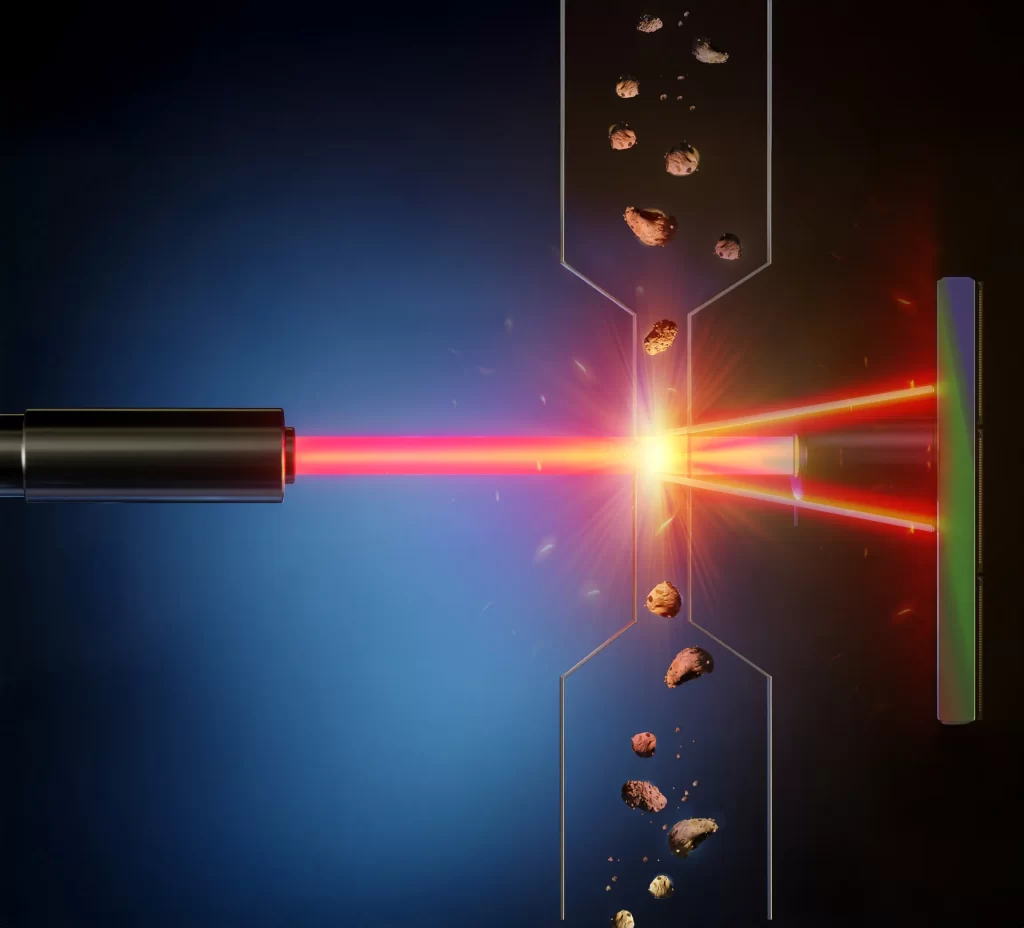

The Effective

Filtration Solution

It is well established by OEMs that an ISO cleanliness level of 11/8/7 is optimal at the injector; therefore, it is essential to have filtration systems capable of ensuring this level of cleanliness.

A filter with a Beta 4>4000 efficiency rating is appropriate for markets where fuel cleanliness levels exceed ISO 21/20/17. It is always crucial that the filter is properly sized for the expected flow rate and that filtration systems are implemented from the point of fuel reception to the dispensing nozzles for operations consuming more than 500,000 gallons annually.

Note: For annual consumption below 500,000 gallons, point-of-use systems (at the nozzle) can be used.

Note: Always account for water and emulsion control—using SAE J1488-certified coalescers for high-volume operations or absorbents for consumption below 200,000 gallons annually.

Note: Bypass filtration of engine oil is highly recommended to maintain lubricant cleanliness below ISO 18/16/13.

This chart clearly illustrates the difference in engine lifespan extension and fuel consumption reduction when using fuel with a cleanliness level that meets OEM recommendations, compared to the fuel currently supplied to equipment in many Latin American countries.

Conclusion

Premature compression loss is a common issue in internal combustion engines but can be mitigated through the selection of appropriate fuel. Choosing high-quality fuels and avoiding low-quality or questionable sources is essential to maintaining engine health and optimal performance over time.

By prioritizing fuel quality, operators can benefit from more efficient, powerful, and durable engines while also contributing to environmental protection by reducing pollutant emissions.