FMS-HFS-4

ULTRA CLEAN OIL

MAXIMUM PERFORMANCE

DESCRIPTION

Particle contamination is the main cause of hydraulic system failures. More than 80% of component wear is particle-induced, with abrasion wear accounting for two-thirds of that figure. An operation that runs with particulate contaminated oil is just like sandblasting the insides of their hydraulic systems. Particle contamination deteriorates metallic surfaces and directly impacts the hoses and seals, leading to leaks, system failures, loss of haulage, diminished production and creates a possible work hazard with increased risk of accidents.

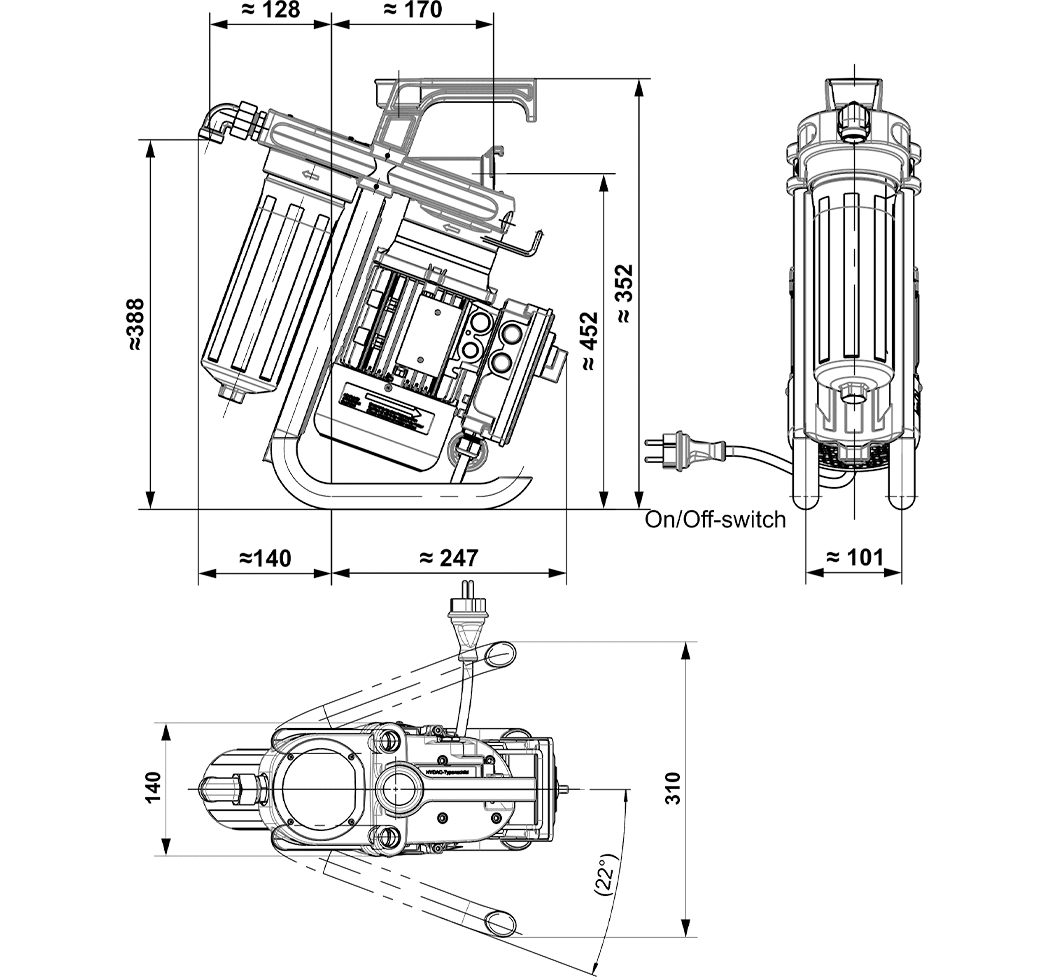

TECHNICAL SPECIFICATION

| Flow Rating | 4gpm (15.14 L/min) max |

| Bypass Opening | 25 psi (1.7 bar) |

| Elements Options | FMS-1/25-P (particulate) & FMS-W25-A (absorbing) |

| Hose Pressure Rating | 30 psig (2.0 bar) @ 150°F (65.6°C) |

| Full vacuum @ 150°F (65.6°C) | |

| Fluid Temperature | 25°F a 150°F (-4°C a 65°C) |

| Hydraulic Oil Sump | 100 gls (21/20/16 down to 15/13/10 in 60 min) |

| Maximum Viscosity | 1,600 SUS (350 cSt) |

| Voltage | 220V, 1 Phase, 60Hz (50Hz optional) |

| Seal Material | Buna N |

| Weight | Single housing – 40 lbs |

| Dual housing – 44 lbs | |

| BackPack version – 39 lbs | |

| (Does not include weight of hose/wands) | |

| Compatibility | All petroleum based hydraulic fluid. |

| Contact factory for use with other fluids. |

BENEFITS

- Longer system uptime

- Lower equipment replacement cost

- Reduced failures and downtime

- Lower total fluid cost

- Lower maintenance cost

- Lower production cost