There Are 3 Contaminants

Particulates, Water, and Sulfur

“We constantly hear the repeated claim that sulfur seems to be the only issue or pollutant in diesel almost as if it were the sole cause of economic, technical, and environmental harm. But how much of this is actually true?“

Why Don’t We Want Sulfur in Diesel?

Sulfur is highly polluting, so reducing its content in diesel is a sound decision. Additionally, it contributes to acidity in the engine when it interacts with water and heat.

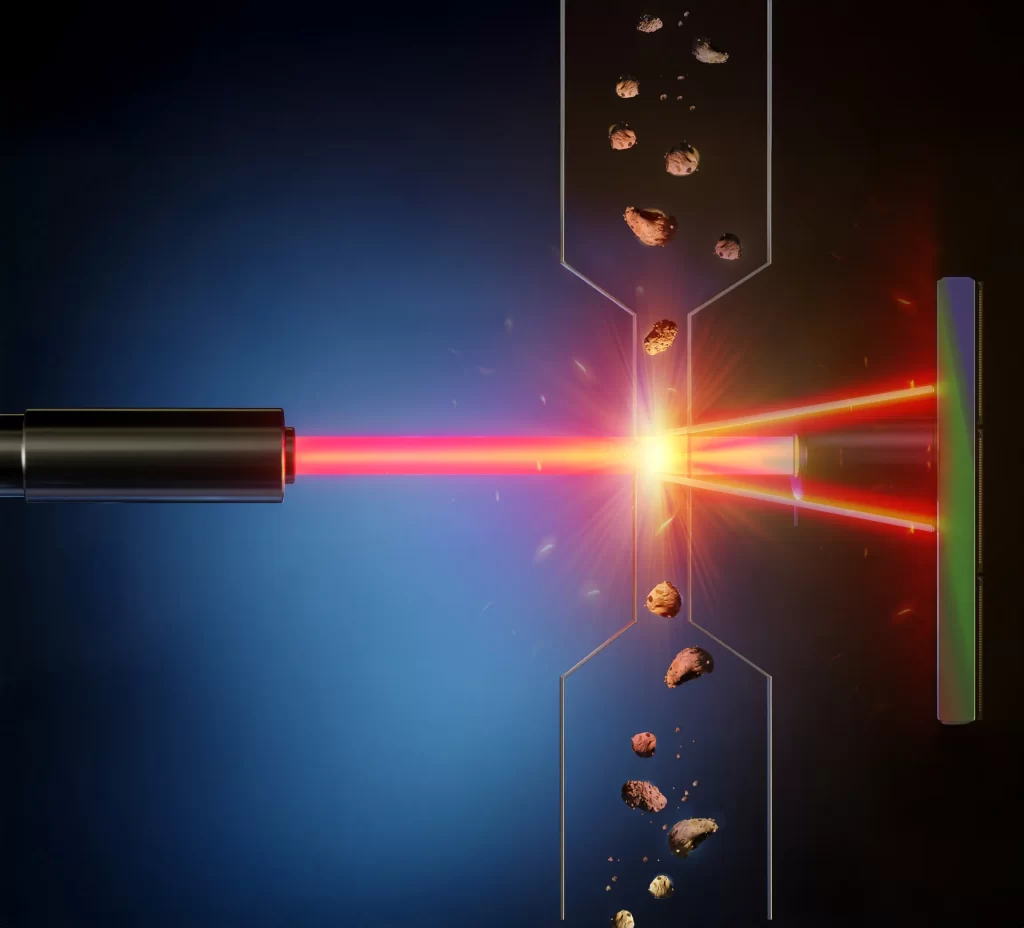

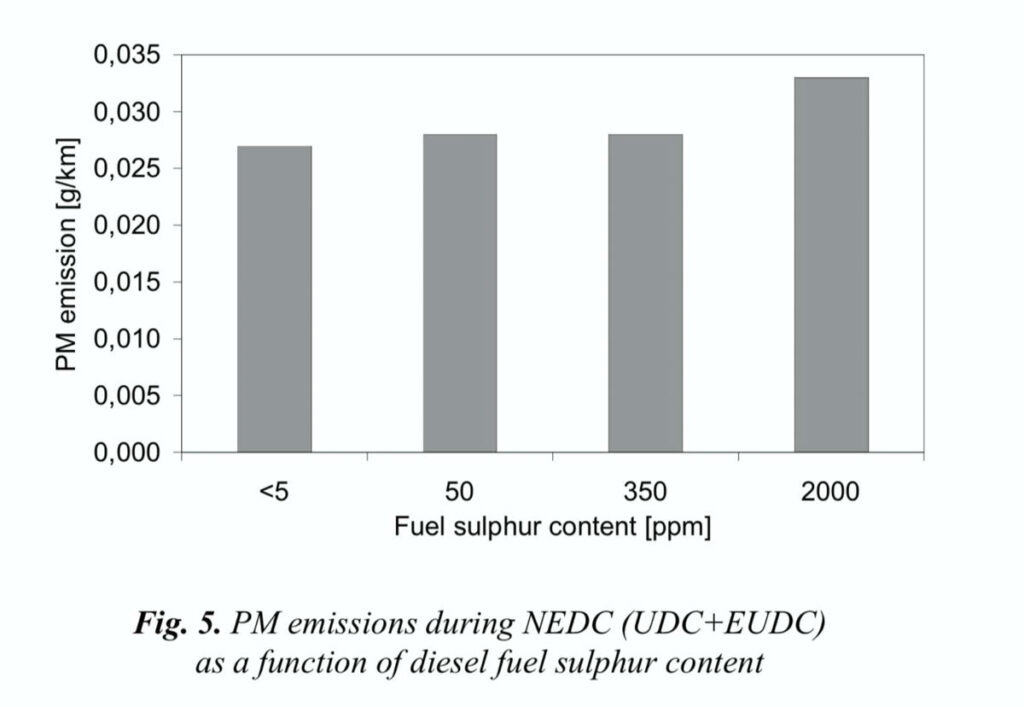

Impact of Sulfur on the Generation of Particulate Matter (PM) in Exhaust Emissions

Sulfur is not the primary source of particulate matter emitted through exhaust systems; rather, the main contributors are the “filterable” solids as defined by ISO 4406.

It is not friction causing

Sulfur is soluble in diesel and is inherently one of its most effective lubricants; therefore, reducing sulfur levels in diesel decreases its lubricity, necessitating the use of additive.

What if it is not friction causing?

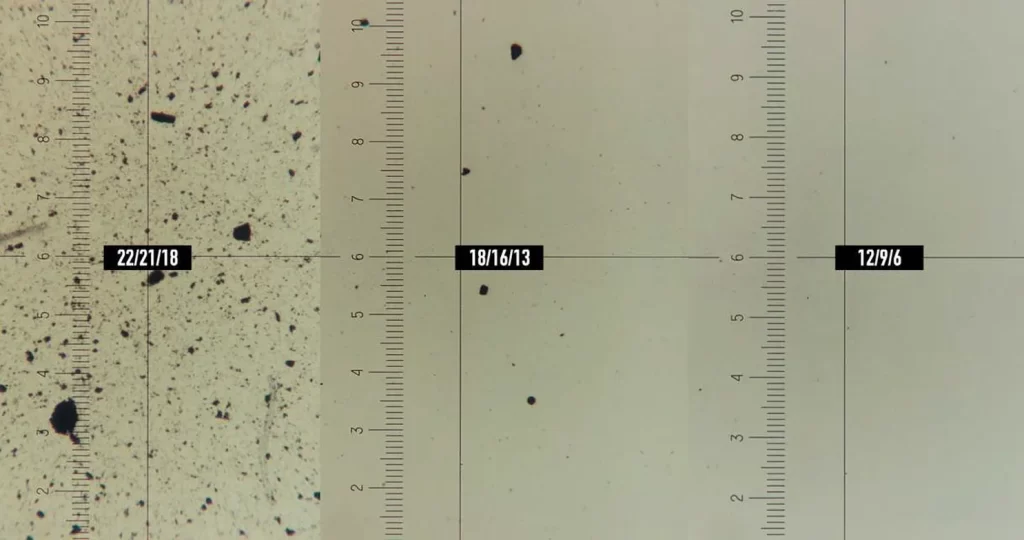

Solid particles are responsible for wear, improper dosing, reduced power, and contaminated oils.

These particles are defined by ISO 4406.

And the water?

Water content is part of the chemical reaction with sulfur and also contributes to the loss of diesel’s calorific value, resulting in increased fuel consumption.

What if we reduce the water?

By reducing the water content, the chemical reaction with sulfur is also decreased to some extent; moreover, up to 15% of the lost power can be recovered.

Let’s explore the impacts

of

diesel contaminants

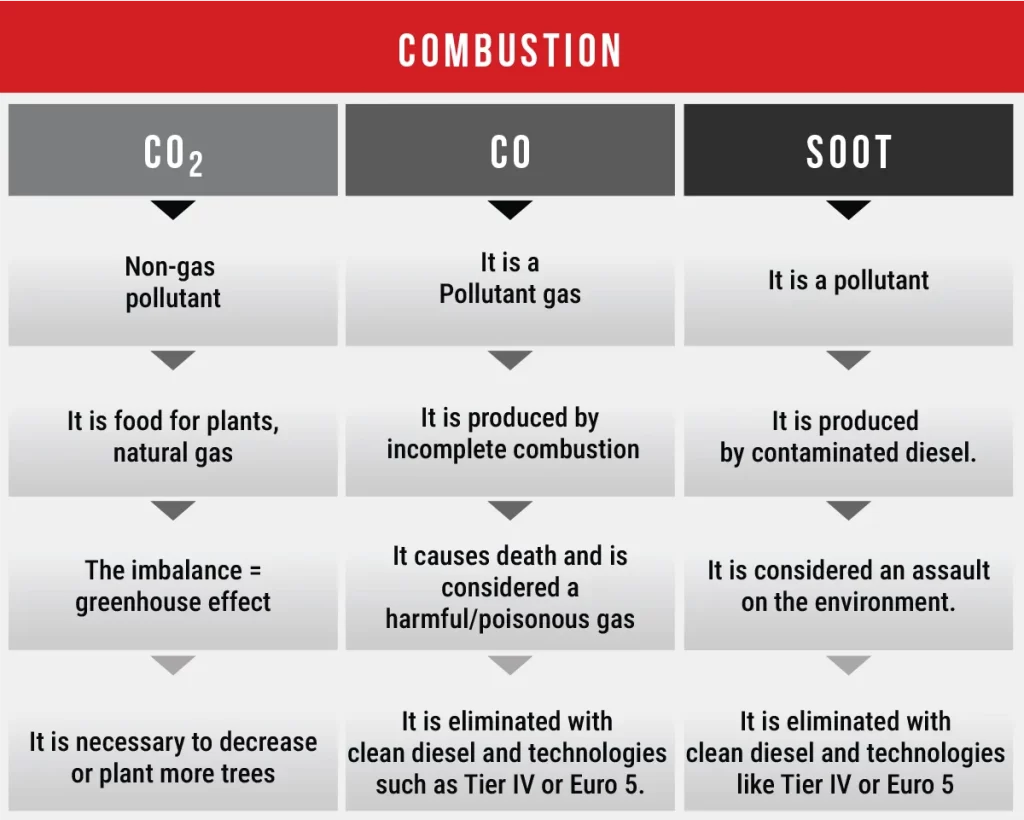

- Environmental pollution

- Acid generator

- Loss of diesel’s calorific value

- Damage to the injection system

- Power loss

- Increased fuel consumption

- Causer of chemical reactions/acids

- Increased consumption of conventional filters

- Damage to the injection system

- Improper dosing

- Power loss

- Higher fuel consumption

- Premature cylinder wear

- Premature loss of compression

- Contaminated oil

- Increased engine wear

- Higher consumption of lubricating oil

The Reality of Diesel in LATAM vs the Maximum

Tolerable and Optimal Levels for Equipment

- Metrovía

- Quito Pollution

Tier IV, Euro 5 & Euro 6

It is commonly believed that sulfur levels prevent the proper functioning of the latest engine technologies. The truth is that in markets like Chile, where sulfur levels are controlled, these engines experience problems due to high levels of solid particles (ISO 4406) and water content.

Similarly, in other markets with high sulfur levels where the ISO 4406 standard (11/8/3) and water content (SAE J1488) are controlled, the impacts of sulfur on the engine are negligible, resulting in multiple benefits for users and the environment. A Euro 6 engine consumes up to 15% less fuel than previous versions, demonstrating significant economic, technical, and environmental advantages in implementing these technologies. However, we cannot simply wait for governments to regulate sulfur levels in diesel, especially when diesel with high solid particle and water content is still being sold without understanding that the greatest harm does not come from sulfur alone but from the combination of all three contaminants.

Users have full control over two contaminants (particles and water); therefore, addressing these allows us to benefit ourselves and the community by taking advantage of clean, dry diesel until governments take action on sulfur. But BEWARE: diesel with low sulfur but high particle and water content will also prevent new technologies from functioning properly.

The chemical reaction of sulfur occurs in Tier I, II, III, IV, Euro 5, and Euro 6 engines alike; however, particles affect the latest generations of engines to a much greater extent and represent the BIGGEST problem.