FMS-3-TP

ULTRA CLEAN OIL

MAXIMUM PERFORMANCE

DESCRIPTION

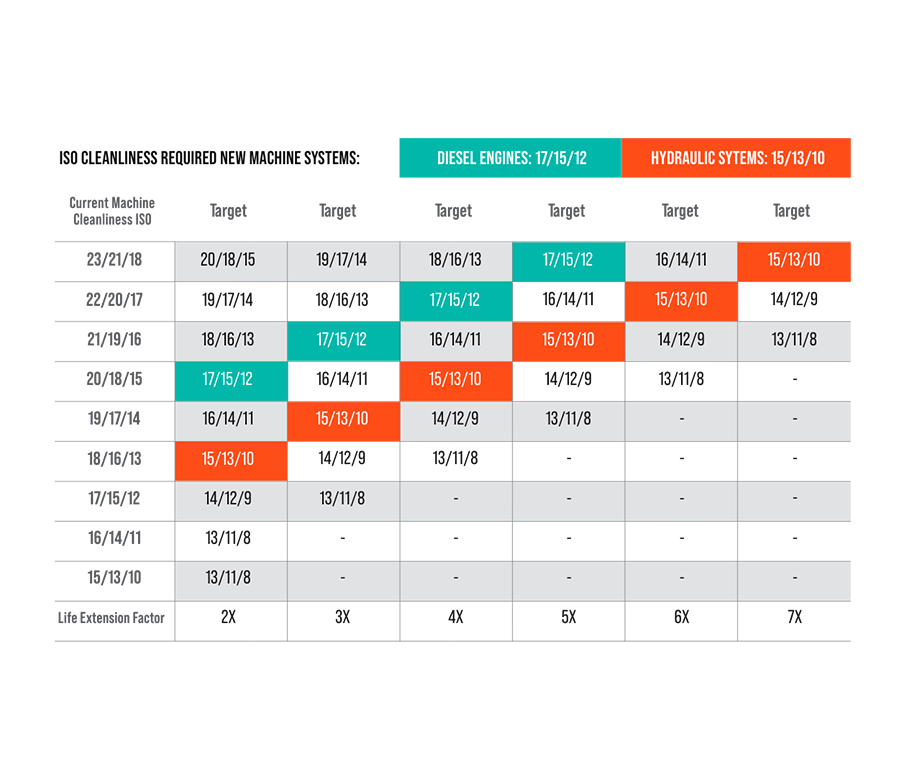

Particle contamination is the main cause of hydraulic system failures. More than 80% of component wear is particle-induced, with abrasion wear accounting for two-thirds of that figure. An operation that runs with particulate contaminated oil is just like sandblasting the insides of their hydraulic systems. Particle contamination deteriorates metallic surfaces and directly impacts the hoses and seals, leading to leaks, system failures, loss of haulage, diminished production and creates a possible work hazard with increased risk of accidents.

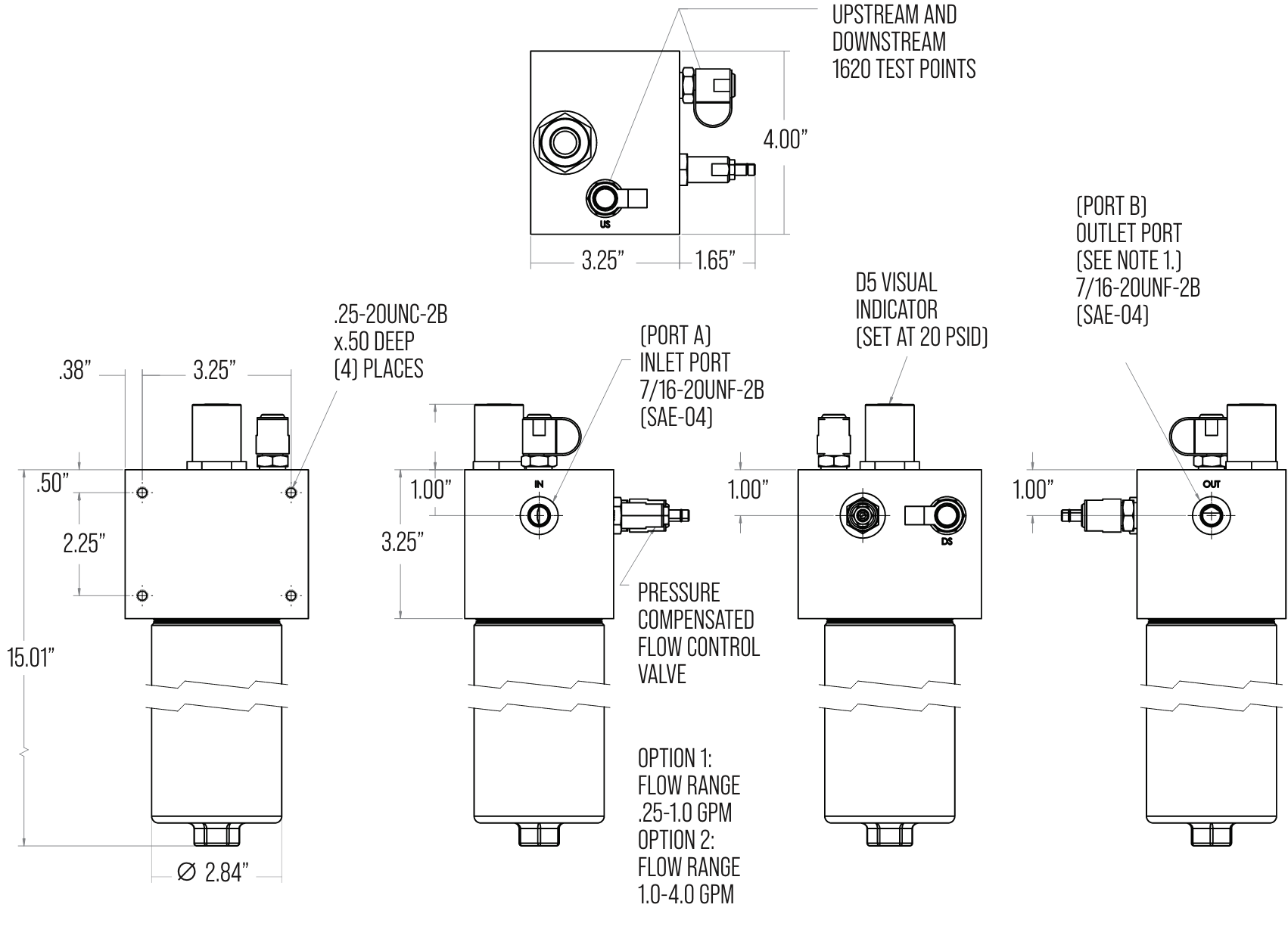

HOUSING TECHNICAL SPECIFICATION

| Max. Flow per Housing | Up to 1 gpm (up to 3 gpmoptional) |

| Porting | SAE-04 |

| Testing ISO | US/DS 1620 Test points |

| Delta P | Pop-up indicator (sensor optional) |

| Pressure compensated flow control valve | 0.1 – 1 gpm (3gpm optional) |

| Bypass Opening | 25 psi (1.7 bar) |

| Elements Options | FMS-1.6-PA (particulate & absorbing) |

| Max. Operating Pressure | 3000 psi (210 bar) |

| Min. Yield Pressure | Contact Factory |

| Temperature Range | -20ºF to 225º (-29ºC to 107ºC) |

| Max. Hydraulic Oil Sump | 100 gls |

| Porting Base | Aluminium |

| Element Case | Aluminium |

| Weight | 6 lbs (2.2 kg) |

| Element Change Clearance | 4.5″ (115 mm) |

ELEMENT TECHNICAL SPECIFICATIONS

| Efficiency | Beta 4>4193 (ISO 16889:99) |

| DHC | 20 grams (MTD) |

| Maximum Flow | 6 gpm |

| Recommended Flow | 2 gpm |

| Dimensions | 12 x 2.1 x 2.1” |

| Weight | 0.3 lbs |

| Housings | FMS-3-TP |